How to lay outdoor micro concrete on a slab (terrace, balcony…)

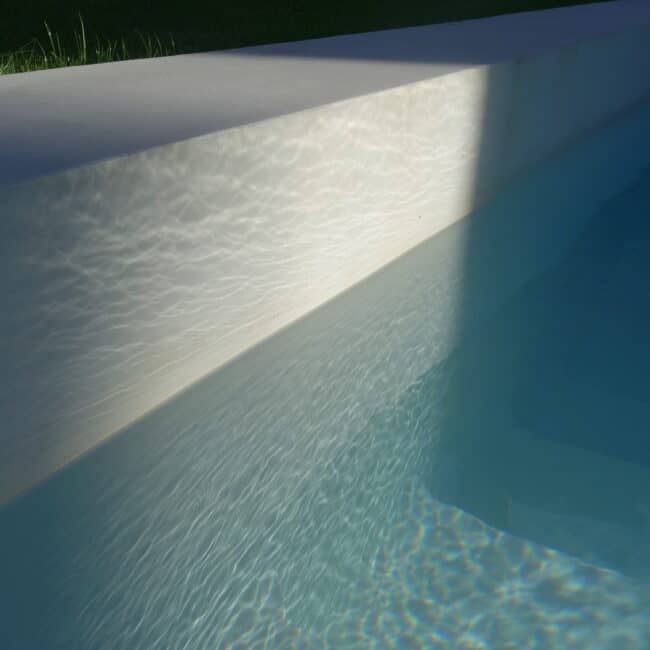

Would you like to install waxed concrete outdoors, for a terrace, balcony or pool deck, for example?

A few key points for laying waxed concrete on an outdoor slab

Here’s everything a craftsman or advanced do-it-yourselfer needs to know about the subject.

Substrate preparation

Application on exterior concrete slabs must be on a substrate complying with DTU 13.3. This document provides for the use of expansion joints at the discretion of the mason and architect.

You will also need :

- expansion joints between the paving and the house, and between the paving and the pool

- a 2% slope to ensure drainage of rainwater

Waxed concrete is applied directly to the slab, which has been thoroughly moistened the day before and, if necessary, the morning of, or even as it is applied in very hot weather, using a small sprayer (to avoid standing water).

This allows the concrete to set slowly and adhere perfectly to the substrate.

Concrete application

In general, both coats of concrete are applied on the same day.

It’s best to apply early in the morning, when temperatures remain cool. If it’s too hot, it’s best to wait until the following day to apply the finishing coat.

Sanding between the two coats with 40-grit sandpaper is recommended.

The use of concrete with SikaLatex admixture and glass fibres is recommended, with a well-laid mesh in accordance with the rules of the trade.

As smoothing progresses, spray on a curing compound. These precautions, along with the use of expansion joints, ensure slow drying, which in turn prevents cracking.

After installation

Seals and gaskets

Joints must be sawn within 24 hours of pouring.

We also recommend apply a sealant on the concrete at the garden’s junction, on the edge of the concrete slab, to prevent capillary suction of water from the ground and watering or rain on the terrace or balcony, or from the swimming pool.

Once both coats are dry, sand lightly with 40/60 grit and apply 2 saturated coats of water- and oil-repellent protection.

Ideally, the surface should remain dry for 48 hours.

Finish

As far as surface finish is concerned, a Flemish liseuse finish gives the best results.

On millimetric waxed concrete, it’s best to avoid flashes, which will be difficult to recover.

The waxed concrete applicator must sand the surface of the slab and remove dust after drying. Installation is carried out on a slab with less than 4% interior humidity.

To ensure that the granulometry of the finish coat meets slippery pool edge standards (PN 18), it should be lightly rubbed with a dry mason’s sponge and sanded.

Maintenance

Exterior waxed concrete can be maintained with a high-pressure cleaner without damaging the surface.

Protection can be renewed after several years, depending on the intensity of use, by simply sanding lightly and reapplying two coats in a day.