The benefits of a micro concrete staircase

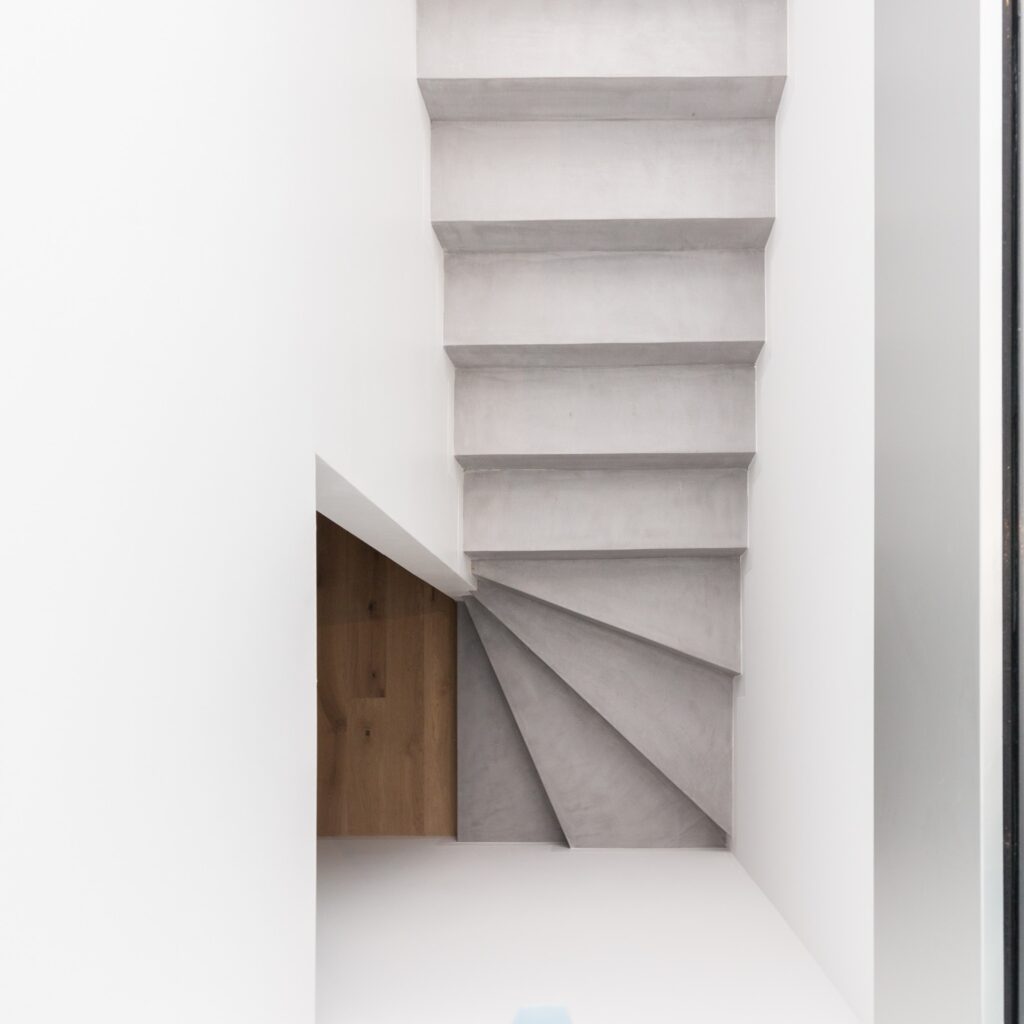

Beyond its functional role, a staircase can also be a piece of architecture in its own right.

In interior design, it has the power to decorate and structure a space.

With its lines, curves and geometry, it plays a unique graphic role.

A treatment in micro concrete can enhance or soften the presence of a staircase, giving it unity and emphasizing its shape.

Then, by playing with colors, micro concrete can mark the contrast with its surroundings or, on the contrary, blend in with the walls or the continuity of the floor.

Micro concrete offers a rich palette of colors that can be applied to steps, floors and walls, indoors and out.

Creating a new staircase in micro concrete

In new construction, the micro concrete staircase is designed on the basis of a reinforced concrete staircase, built with a formwork by a masonry contractor. This determines the shape of the staircase and, with the right dosage of concrete, ensures that the structure will stand the test of time.

When planning the construction of a new staircase with a masonry company, if you choose to create it in a concrete monoblock, simply specify that the Marius Aurenti micro concrete coating will be 2 mm thick on the treads and 1 to 2 mm thick on the stringers and undersides of the staircase.

Once the staircase has been formworked and poured, and the concrete is fully cured (i.e. with less than 4% moisture content), the micro concrete can be applied.

This installation requires more or less intense sanding with a diamond surfacer or 40-grit grit sanding to perfect the surface, removing spalls, runs and other roughness defects.

As masonry concrete is a porous product, porous substrate primer must be applied to prepare the surface.

If it appears necessary to reinforce the solidity of the steps, or to compensate for problems of micro-cracking in the concrete, preparing the steps with sanded EPX2 epoxy resin can be a good solution.

The epoxy resin can also be used to bond stair nosings in the form of metal profiles, in brass, for example, or in wood, to create a contrast of materials. By default, this preparation is not necessary if the masonry is correctly executed.

Micro concrete is applied more thickly to the faces and corners of the steps, which have been previously rounded by sanding, to avoid injuries caused by sharp edges. On stringboards and under surfaces, as these are purely decorative areas, an application of 1mm is sufficient.

The surface of steps must be protected with reinforced varnish, as must floors and intensive areas (300g/m2).

Protection can be lighter, with lower consumption, on stringers and undersides (150 to 200g/m2 of varnish).

For new-build projects, and in the context of a more minimalist architecture – less cumbersome than a concrete structure that requires the use of many materials – it is possible to consider other construction methods.

The staircase can be made of metal, steel, with an inlay on the walls, or suspended from the floor and walls. There are no real limits to the creation of a metal staircase.

How can I make it compatible with waxed concrete?

It is not possible to lay micro concrete directly on a metal surface. Expansion of this material may cause the concrete to crack or the substrate to delaminate. Marius Aurenti does not recommend this type of installation.

However, it is possible to imagine metal frames assembled with precast Smart-Up high-performance concrete slabs.

High-performance fiber-reinforced concrete can be left raw or covered with a layer of Marius Aurenti millimetric micro concrete.

This finish has the advantage of ensuring color accuracy and a good degree of slipperiness and step protection.

The other solution, still based on metal frames, is to use Vigorn panels, cut and installed inside these frames, in a thickness of 14 or 24mm, which is what we recommend for this type of use.

Vigorn panels, like UHPC slabs, can be covered with micro concrete.

In the case of a wooden staircase, it’s a question of playing on the layout between the wooden structure and the use of Vigorn slabs cut to the dimensions of the steps.

Their thickness of 14 or 24 mm makes them extremely lightweight, while their composition enables them to adapt perfectly to the wood.

(See Vigorn slabs and the Manufacture workshop, which can produce standard slabs as well as made-to-measure items to drawings).

Renovating a staircase with waxed concrete

If the staircase is to be renovated, and if it is made of painted concrete, it needs to be mechanically sanded with a diamond sander to remove all the paint, allowing the concrete to adhere properly to the structure itself.

Once the structure has been stripped bare, the work is carried out as if it were new.

If the staircase is structured in wood, the treads can be replaced by Vigorn slabs in 14 or 24 mm, cut to the exact size of the treads.

Please note: fields and rounded stair nosings are required.

If the staircase is tiled with wooden, tiled or metal stair nosings, the first thing to do is check the adhesion of the tiles. Anything that is not a member must be removed. This is done by tapping on the tiles to remove any that sound hollow. The void left behind can then be filled with epoxy mortar, or by ensuring a perfect bond between the tiles. If removal is carried out on the stair nosing, check whether the problem is generalized to all stair nosings, or whether they are adherent. Stair nosings in perfect condition can be retained, but if they are to be removed to create a uniform micro concrete staircase, the stair nosings must be removed without damaging the existing tiles, then the new stair nosings must be formed and poured.

If the staircase is tiled with wooden, tiled or metal stair nosings, the first thing to do is check the adhesion of the tiles. Anything that is not a member must be removed. This is done by tapping on the tiles to remove any that sound hollow. The void left behind can then be filled with epoxy mortar, or by ensuring a perfect bond between the tiles. If removal is carried out on the stair nosing, check whether the problem is generalized to all stair nosings, or whether they are adherent. Stair nosings in perfect condition can be retained, but if they are to be removed to create a uniform micro concrete staircase, the stair nosings must be removed without damaging the existing tiles, then the new stair nosings must be formed and poured. We recommend the use of epoxy resin and SQ 40, 60 or 80B sand, depending on the filling required.

The resin has a high adhesion capacity, superior for bonding to concrete. It also offers the advantage of efficient processing, as polymerization takes place very rapidly. Two days after pouring, it is possible to work directly on the perfectly dry structure.

In terms of mechanical strength, the resin often exceeds 100 MPa, which is recommended for stair nosings.

Another option is to remove the old stair nosings and replace them with metal strips or L-shaped strips, which are particularly suitable for staircases in public places. In the hotel industry, for example, repeated impacts with suitcases can damage the edges of steps.

Steps in the process (see section on applying waxed concrete to tiles)

1. Diamond sanding of tiles.

2. Sandblasted epoxy resin.

3. Laying waxed micro concrete (making sure it is slip-resistant).

4. Varnish protection.

CREATE AN OUTDOOR CONCRETE STAIRCASE

An outdoor staircase in micro concrete can be built either on a conventional concrete structure, cast in situ with formwork and reinforcement, or on prefabricated concrete. In both cases, mechanical surface treatment involves appropriate sanding to adjust flatness and anchor the micro concrete to the concrete structure.

Basically, this involves creating an irregularity and removing any remnants of curing compounds or formwork oils.

The more or less accentuated fineness of the concrete grain on the tread will ensure easy maintenance or, on the contrary, more effectively grip bare or shod feet on outdoor or pool stairs.

Once this sanding has been carried out using a diamond disc, or a simple sanding disc if this is sufficient, a treatment with a porous backing will block the base.

The next step is to apply a conventional two-coat finish 2 mm thick to optimize the mechanical quality of the micro concrete.

In fact, the intense use of this type of work and its exposure to the elements outdoors will require 2 mm of coverage.

As with all staircases, the surface finish is designed to achieve the appropriate license rating for its use, and the protective treatment to facilitate maintenance.

What are the advantages of a micro concrete staircase?

A wide choice of colors

Marius Aurenti offers a wide choice of colors, more than 71 colors and the possibility of chromatic research.

Either to contrast with the rest of the room’s decor, or on the contrary to have the continuous look of the bc already present on the floor and staircase, which guides the visitor into the house and enlarges the space.

Micro concrete is capable of coating not only the treads but also the stringers and undersides, giving a one-piece unit to a staircase that is particularly aesthetically pleasing.

Micro concrete is a seamless, flat surface that’s easy to clean.

our online products Waxed Concrete

Points to watch when building a micro concrete staircase

1. the stairnosing must be rounded to avoid sharp edges.

2. The stair nosing must not be too thin to absorb any impact.

3. For intensive use in public places, for example, the installation of stair nosing is recommended.

4. Care must be taken to ensure that the material has the necessary roughness for good grip in bare feet, shoes and even socks. This question also applies to tiled, wooden or even glass staircases.

5. While laying micro concrete on a staircase can be done relatively easily, good site organization is necessary to guarantee access to the upper floor during the work. A tip: alternate every other step to keep moving.

Concrete staircases: A bold design for your interior

Staircases are much more than just a means of connecting different levels of a home.

They can become a real centerpiece, an architectural sculpture that structures and sublimates the space.

Among noble materials, concrete is the ideal choice for both aesthetic and functional design of timeless staircases.

With its clean lines and natural robustness, concrete brings a touch of raw elegance to your interior.

Whether curved or straight, with suspended or recessed treads, concrete staircases offer an infinite range of possibilities for creating unique rooms imbued with character.

Their mineral appearance and reassuring solidity also make them a wise choice from a practical point of view.

A variety of finishes allow you to personalize the look of your staircase: smooth concrete, micro concrete, rough concrete or even mass-colored concrete.

Combined with other noble materials such as wood, metal or stone, concrete blends harmoniously into the most contemporary interiors.

Inspiration Marius Aurenti

Sublime project in this Marseille house with a floor in Marius Aurenti waxed concrete in Colette blue; it offers perfect continuity between the rooms.

Designed by Bruno Crespin/ Architecte François

CONCRETE COLOR CHART 71 COLORS – MARIUS AURENTI