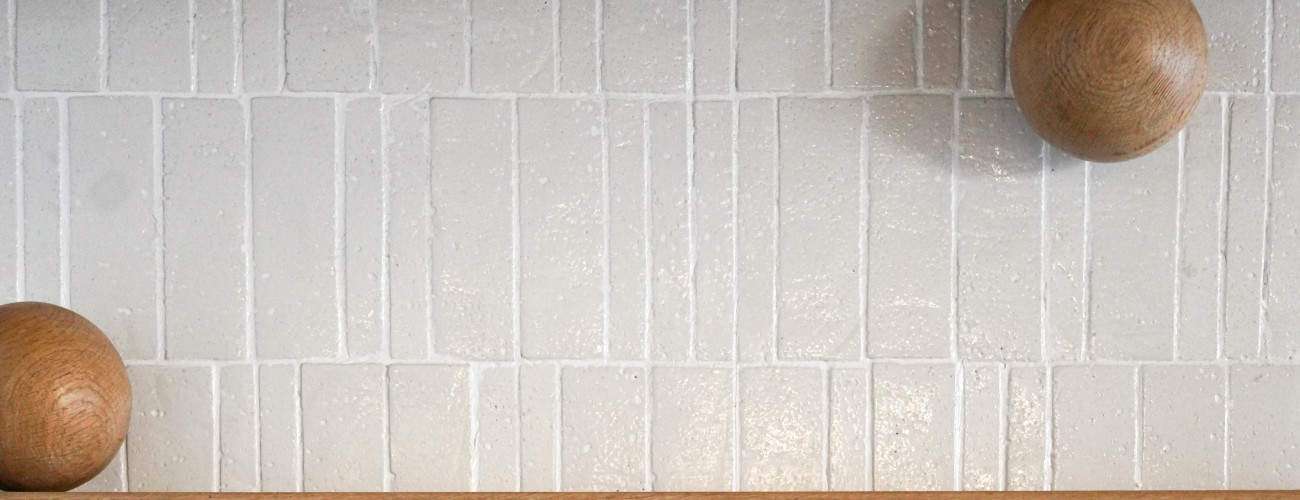

The Carqis Concrete Tile is a unique, hand-crafted creation born of a project in Carqueiranne, in the South of France. Designed for an elegant seaside house by architect Nancy Geernaert of Just’in Design, this tile was a response to the desire for a raw, random material. So we developed a mass-pigmented concrete tile, offering variations in casting and coloring that provide an unprecedented sensory, visual and tactile experience.

The name “Carqis” reflects its origins: “Carq” refers to Carqueiranne (South of France), the town where this tile was born, and “is” evokes “pertuis”, an ancient term meaning “little holes”, in homage to the delicate irregularities that characterize each piece.

Material, texture, colors

Carqis Concrete Tiles plunge us into the Mediterranean world of Marius Aurenti.

Our expertise in materials and craftsmanship has led to the creation of modern, contemporary concrete tiles for interior design.

Carqis innovates in its materials to bring a singularity and a new aesthetic, to bring nature and light into play through the relief and asperities of each tile.

A singular tile

- Designed in high-performance fiber-reinforced concrete

- Available in 20 colors

- Rough, matte or gloss finish

- Protection with high-resistance varnish

- Manufactured in France by Marius Aurenti

Format *

- Small size: 15 x 2.4 cm x 1 cm (5.9in x 0.95in x 0.39in)

- Large format: 15 x 5 cm x 1 cm: (5.9in x 1.97in x 0.39in)

Sales unit: 0.45 m2 box

* As an indication, the tolerance of a tile is + or – 1 mm in thickness.

Destination

Carqis Concrete Tiles are ideal for dry, low-humidity and medium-humidity interior rooms, objects, displays and furniture.

Availability

Carqis Concrete Tiles have a manufacturing lead time of 8 to 12 weeks.

Find out more in the technical data sheets.

Order your samples and color charts from Matériautèque.

The product Carqis concrete tiles by Marius Aurenti

BUY ONLINE

Carqis Concrete Tiles are made to order, which you can do through your distributor or the Marius Aurenti showroom, and online at the Marius Aurenti e-shop.

Give free rein to your creativity by integrating Carqis tile into your projects, and play with patterns and repetitions to create unique layouts, often without the need for additional cutting.

CARQIS Carreau béton

122.40€ – 139.20€ HT

Choix des options

Carqis 20 colors – Marius Aurenti

Technical data sheets (PDF version)

Technical data sheets (PDF version)

Issue of 10/27/2023

Mass-tinted high-performance concrete tile

Presentation

This concrete tile plunges you into the Mediterranean world of Marius Aurenti. Carqis are hand-cast in France, unique and dotted with a thousand little holes, in magnificent small formats.

Concrete and mineral pigmentation in the mass, they can be left unfinished or protected by a matte or gloss varnish.

AREAS OF USE

Decorative tiles for interior use. Straight or herringbone installation.

COMPOSITION

High-Performance Concrete (HPC)

LENGTH AND WIDTH

15 x 2.4 cm (+/- 1 mm) 15 x 5 cm

(Tolerance +/- 1 mm)

THICKNESS

1 cm

(Tolerance +/- 1 mm)

COLORS

20 colors available (see Marius Aurenti IRIS color chart)

FINISHES

Rough, Matt (High-Performance Varnish), Gloss (High-Performance Varnish)

PACKAGING

Packaging includes 2 small Carqis (2.4 x 15 cm) for 1 large Carqis (5 x 15 cm). (see page 6)

1 Box of 66 Carqis tiles – size 15 x 5 cm

– approx. 0.45 m² + 1 box of 126 Carqis tiles – size 15 x 2.4 cm – approx. 0.45 m².

Carton dimensions: 21 x 15.5 x height: 15.5 cm

Total weight/cartons: approx. 8.8 kg

MAINTENANCE

Use a PH-neutral cleaner from Marius Aurenti.

TECHNICAL SPECIFICATIONS AND PERFORMANCE

Product appearance: matte or gloss

Mechanical properties of HPC at 28 days :

Flexural strength (Rf) – 4x4x16 cm prism: 11MPa

Compressive strength (Rc) – 4x4x16cm prism: 75 MPa

Implementation

Carqis tiles must be laid in accordance with the rules of the trade and in compliance with DTU 52.2 in force.

TARGET AREAS :

Dry or low-humidity areas (EA) and medium-humidity areas (EB).

PERMISSIBLE SUPPORT

Interior walls :

Nomenclatures of targeted media :

- Non-water-repellent (cardboard faces) and water-repellent plasterboards.

- Plasterboard partitions

- Shaped walls in bare aerated concrete blocks

- Gypsum plaster on masonry walls and partitions

- Cement-based plasters on concrete or masonry walls and partitions

- Concrete walls or precast concrete panels

New or old substrates will be sanded and then mechanically vacuumed. Substrates must be sound, clean, crack-free and cohesive (surface scraping with a metal object must not produce dust, grain or scale; tensile strength in perpendicular tension > 0.5 MPa in general), dry, flat (deflection less than 5 mm under the 2-meter straightedge and 1 mm under the 20-cm straightedge), normally porous (between 1 and 5 minutes in the water drop test), clean (notably free of grease, dust and any loose parts), in compliance with current DTU standards.

CONDITIONS OF USE

The choice of bonding product is based on criteria defined according to the standardized characteristics and properties declared by manufacturers, in keeping with the purpose and use of the premises or the exposure of the tiled structure.

It is essential to observe the application conditions for the adhesive used. It is essential to refer to the Technical Data Sheet for the adhesive used.

Gluing must not be carried out on frozen substrates.

STORAGE AND SAFETY

Store in original, unopened packaging, away from sunlight and frost, in a temperate room (+15°C minimum).

For further safety information, please consult the Safety Data Sheet.

APPLICATION TEMPERATURE

AMBIENT TEMPERATURE >+ 5°C and <35°C

SUBSTRATE TEMPERATURE >+5°C and <30°C

APPLICATION EQUIPMENT

Tile-cutting tools: dry cutting systems, diamond hole saws, suitable clamps and grinders.

Laying tools: Tile adhesive, notched trowel, cross-bars to help adjust the flatness of the finished work.

TILE CUTTING

The preliminary layout determines where the tiles are to be cut. Cut-outs are made using the tools described in the section on installation equipment. Particular care must be taken when making circular and end cuts.

ENCOLLAGE

To avoid adhesion defects, the back of CARQIS tiles must be free of dust. C2 thin-set mortar (1) is applied to the substrate with a trowel (single-set), then spread with a notched trowel suited to the product. The surface glued at one time must not exceed the open time of the gluing product (generally between 10 and 20 minutes).

Consumption and gluing method must comply with the following rules (refer to DTU 52.2):

| CONSUMPTION MORTAR-GLUE C2(1) | SPATULA NOMENCLATURE | |

| CARQIS TILES 15 X 2.4 CM | 1.5 kg powder /m² | U3 (square teeth 3mmx3mmx3mm) |

| CARQIS TILES 15 X 5 CM | 3.5 kg powder /m² | U6 (square teeth 6mmx6mmx6mm) |

Caution: only a D1 or D2 adhesive (paste) is recommended for glue-down installation:

- on a plasterboard partition (S8 nomenclature) and

- on gypsum-based plaster (nomenclatures S4 and S5).

Adhesive consumption: 3 kg/m² (V6 spatula – 6mm triangular teeth)

Glue-down installation on water-repellent plasterboard partitions (S9 and S10 nomenclatures) is excluded in mortar-glue and adhesive (paste) versions.

On concrete substrates, only C2 thin-bed mortar is recommended.

If 2 different sizes of Carqis tile are used on the same job, use the higher consumption of thin-set mortar and the associated spatula.

In the absence of a specific standard for spatulas, the properties and characteristics announced by the C2 mortar-glue manufacturer should be used as the basis for selection.

TILE INSTALLATION

Ceramic tiles are positioned on the substrate. Any mortar-glue build-up should be cleaned and the joints hollowed out. Careful positioning of ceramic tiles is essential, because once the tiles have been placed on the substrate, they are difficult to move.

JOINT WIDTH

Zero joint installation is not permitted. Installation with aligned or staggered joints is covered in this document. The minimum joint width is 2 mm.

JOINTING

With normal-hardening pointing mortar, grouting takes place the next day at average temperatures (15°C to 20°C). For temperatures below 15°C (cold and/or damp weather), this time may be extended.

CLEANING CARQIS TILES AFTER GROUTING

Cleaning removes installation residues. Cleaning should be carried out with water after the joints have been made, before the pointing mortar has fully set.

CARQIS , INSPIRING POSE IDEAS: 2 FOR 1

Carqis innovates in its materials to bring a singularity and a new aesthetic, to bring nature and light into play through the relief and asperities of each tile.

We recommend using two small 2.5 x 15 cm tiles for one large 5 x 15 cm tile.

For 1 m² :

140 tiles 2.5 x 15 cm and 70 tiles 5 x 15 cm

For 1 m² :

140 tiles 2.5 x 15 cm and 70 tiles 5 x 15 cm

Treatment of singular points

WALL/CEILING AND WALL/FLOOR CONNECTION

Under no circumstances should Carqis tiles come into contact with the underside of the ceiling or the rough or finished floor.

SANITARY FIXTURE CONNECTIONS AND WALL PENETRATIONS

The connection between sanitary fixtures and the wall, as well as wall penetrations, must be treated before Carqis tiles are laid, to prevent water infiltration (see NF DTU 60.1). Once the covering has been laid, the 5 mm gap between the edge of the fixture and the first row of tiles is filled by the tiler with a sanitary sealant complying with standard NF EN 15651-3. A profile can be used instead of putty.

OUTWARD OR INWARD ANGLES

Accessories or profiles as defined in NF DTU 52.2 P1-2 can be used to mechanically protect the edges of cladding elements, to join the cladding element to other materials and to create the corners of tiled surfaces.

These profiles are designed for glue-down installation, whose thickness must match the thickness of the cladding element. It is embedded in the C2 adhesive mortar when the Carqis tiles are laid.

These profiles can be made of ferrous metal (e.g. stainless steel), non-ferrous metal (e.g. aluminum or brass) or plastic in a variety of shapes and colors.

DIVIDING, PERIPHERAL OR EXPANSION JOINTS

This is a completely reserved space, filled during finishing work with a mastic that complies with NF EN ISO 11600 and does not stain ceramic tiles. A metal profile or PVC profile with a compressible seal can also be used. The joints are spaced at approximately 60 m² intervals (corresponding to horizontal joints no more than every 6 m and vertical joints no more than every 10 m).

A 25E “sanitary” sealant is used for damp or collective premises.

Given the specific nature of materials and building sites, it is essential to understand the risks involved by carrying out preliminary validation tests adapted to the project. These tests are to be carried out, in agreement with the company, by the putty supplier in accordance with one of the 2 ISO 16938-1 or 16938-2 standards.

POSTS AND CURVED SURFACES

The maximum width of Carqis tiles permitted depends on the radius of curvature R of the substrate, as shown in the table below:

| BENDING RADIUS (IN CM) | 15 | 60 | 140 | 250 |

| MAXIMUM WIDTH (IN CM) | 5 | 10 | 15 | 20 |

On posts or curved surfaces, Carqis tiles must be laid using double gluing, with a level of adhesive consumption that ensures a full bath with no air voids around the perimeter of the tile.

Acceptance of work

FLATNESS

The tolerances of the finished coating are identical to those of the substrate, increased by the tolerance of the tile. Out-of-roundness is the distance between the edges of 2 adjacent elements, measured perpendicular to the bonding plane. This is due to tolerances in the substrate and in the manufacture of the elements. The permissible flush must be less than a third of the width of the joint between the tiles, plus the tolerance of the tile.

FINAL ASPECT

The final appearance of the cladding can be assessed from a distance of around 1.65 m, using non-glancing lighting (angle between cladding and incident natural or artificial light greater than 45°).

JOINT ALIGNMENT

A 2 m rule must not reveal an alignment difference of more than 2 mm, to which must be added the tolerance allowed on Carqis tile dimensions.

COMMISSIONING TIME

Premises can be occupied at least the day after grouting. In all cases, please refer to the joint mortar manufacturers’ technical data sheets.

Further information

Handmade, Carqis tiles are unique products.

The care taken in their manufacture does not prevent variations in appearance and color. Carqis tiles feature a matt or glossy surface protection.

Despite the high performance and qualifications of this protection, it is not immune to long and repeated exposure, which can damage Carqis tiles.

Avoid prolonged or permanent contact with aggressive chemicals such as acids, alkalis, vinegar, solvents, bleach, hydroalcoholic gel, etc.

Hydroalcoholic gel sprayed onto the surface of Carqis tiles can cause irreversible damage. Surfaces at risk of exposure must be perfectly protected.

Carqis tiles are not recommended for use in contact with hot oils (e.g. kitchen splashbacks).